2025 Top Hydraulic Press Brake Buying Guide for Efficient Metalwork

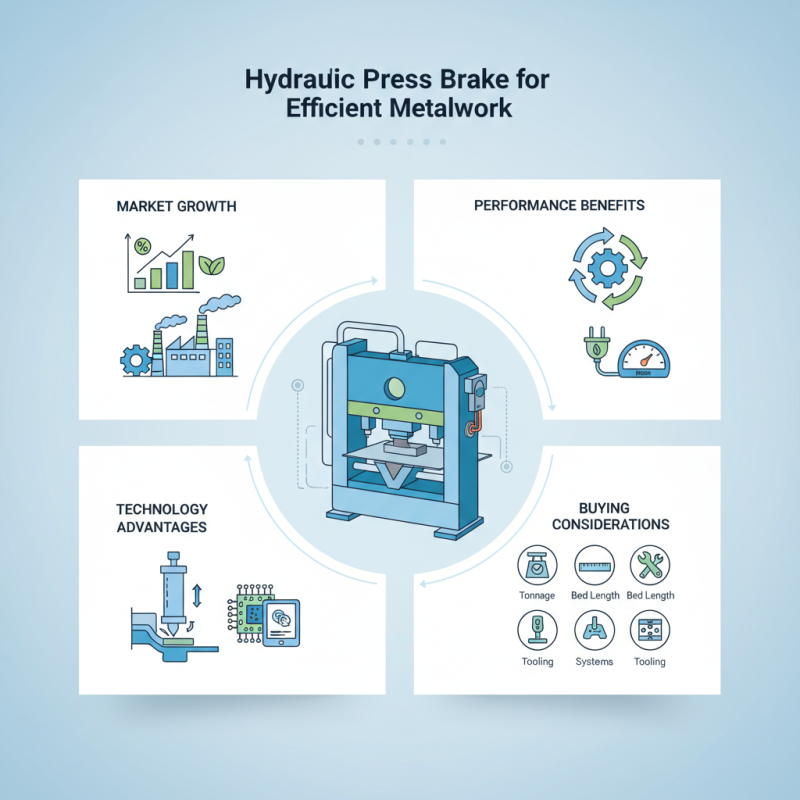

In the ever-evolving landscape of metal fabrication, investing in the right tools is paramount for enhancing productivity and ensuring precision. As highlighted by the latest industry reports from the Fabricators & Manufacturers Association, the demand for hydraulic press brakes is projected to increase significantly, with the market expanding at a compound annual growth rate (CAGR) of over 5% through 2025. This uptick is driven by the growing need for efficient metalworking solutions capable of meeting modern manufacturing demands.

Hydraulic press brakes stand out in their ability to deliver reliable and accurate bending operations, making them an essential asset in any metalworking facility. According to a recent study by the International Institute of Welding, the effectiveness of hydraulic systems in press brakes leads to reduced energy consumption and enhanced operational performance compared to traditional mechanical systems. As manufacturers strive for efficiency and sustainability, the hydraulic press brake emerges as a crucial component in achieving these objectives, ensuring not only high-quality output but also a competitive edge in the marketplace.

With multiple options available, understanding the key factors in selecting a hydraulic press brake is vital for making informed purchasing decisions. From tonnage and bed length to control systems and tooling capabilities, this guide will navigate through essential features and considerations that contribute to optimizing your metal fabrication processes. As we look towards 2025, equipping your workshop with the right hydraulic press brake can significantly influence your operational efficiency and product quality.

Understanding Hydraulic Press Brakes: Basics and Functionality

Hydraulic press brakes are essential tools in the metalworking industry, designed to bend and shape metal sheets with precision and efficiency. The basic functionality of a hydraulic press brake revolves around using hydraulic force to exert pressure on the metal, which is positioned between a die and a punch. This process allows for accurate bends, folds, and angle adjustments, ensuring consistency in production. According to a recent industry report, the global press brakes market is expected to reach $7.5 billion by 2025, reflecting the growing demand for advanced metal fabrication techniques.

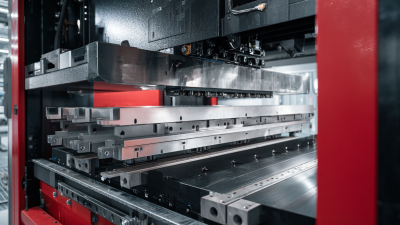

Understanding the mechanics of hydraulic press brakes involves familiarization with their components, such as the ram, the hydraulic system, and the control mechanisms. The hydraulic system operates under Pascal’s law, where pressure applied to a confined fluid is transmitted equally in all directions. This fundamental principle enables significant force multiplication, allowing press brakes to handle heavy materials with ease. Industry data indicates that hydraulic press brakes can achieve tonnages ranging from 20 tons to over 1,000 tons, showcasing their versatility across various manufacturing sectors. Moreover, modern advancements in technology have introduced CNC controls, which enhance operational efficiency and accuracy, catering to the intricate demands of contemporary metalwork.

Key Factors to Consider When Buying a Hydraulic Press Brake

When purchasing a hydraulic press brake, several key factors must be considered to ensure the equipment meets business needs efficiently. First, the bending capacity is crucial; it determines the maximum thickness and width of material that the press brake can handle. Buyers should assess their specific metalworking projects to choose a machine with suitable tonnage and bed length. Additionally, it is essential to evaluate the materials typically processed, as different metals may require unique bending capacities and tooling adaptations.

Another significant aspect is the precision and repeatability of the machine. High-quality hydraulic press brakes should offer accurate positioning to ensure consistent results across different batches. Features such as programmable controls and back gauges can enhance efficiency by enabling automated setups. Furthermore, understanding the ease of use, including operator interface and maintenance requirements, contributes to overall productivity and minimizes downtime. Taking these factors into account can lead to a more informed purchase, aligning the press brake capabilities with operational goals.

Top Brands and Models for Hydraulic Press Brakes in 2025

In 2025, the market for hydraulic press brakes is expected to expand significantly, driven by the growing demand for precision metal fabrication across various industries. According to recent industry reports, the hydraulic press brake market is projected to reach a valuation of approximately $3 billion by the end of 2025, with a compound annual growth rate (CAGR) of around 4.5%. This growth is fueled by advancements in technology and increases in production capabilities that enhance the efficiency and effectiveness of metalworking processes.

When considering the top brands and models for hydraulic press brakes in 2025, it is essential to focus on features such as tonnage capacity, precision control systems, and programmability. Models equipped with advanced CNC systems are gaining popularity for their ability to deliver consistent results and reduce operator fatigue. The integration of automation technologies, such as robotic loading and unloading systems, is also transforming how these machines are utilized on the shop floor. As manufacturers seek to enhance throughput and reduce operational costs, selecting hydraulic press brakes with robust performance metrics and reliable warranty support will be critical considerations.

Investing in a well-reviewed model can make a substantial difference in operational efficiency. Recent studies indicate that businesses utilizing high-quality hydraulic press brakes experience up to a 30% increase in productivity when compared to those using outdated or less efficient models. As the industry evolves, staying informed about the evolving features and capabilities of these machines will be crucial for companies aiming to maintain a competitive edge in the metalworking landscape.

2025 Top Hydraulic Press Brake Buying Guide for Efficient Metalwork

| Model | Tonnage | Max Bending Length (mm) | Control Type | Price (USD) | Warranty |

|---|---|---|---|---|---|

| Model A | 120 | 2500 | CNC | 12,000 | 2 Years |

| Model B | 150 | 3000 | Manual | 10,500 | 1 Year |

| Model C | 200 | 3500 | CNC | 15,000 | 3 Years |

| Model D | 100 | 2200 | Manual | 8,000 | 1 Year |

| Model E | 250 | 4000 | CNC | 18,000 | 4 Years |

Maintenance Tips for Optimizing Hydraulic Press Brake Performance

To ensure optimal performance of hydraulic press brakes, regular maintenance is essential. First, operators should frequently inspect the hydraulic fluid levels and the condition of the fluid itself. Contaminated fluid can lead to inefficiencies and potential damage to the system. Using high-quality hydraulic fluid and replacing it according to the manufacturer's guidelines will help maintain the performance and longevity of the equipment.

Another critical aspect of maintenance is checking for leaks in the hydraulic system. Any signs of leaking fluid can indicate underlying issues that need immediate attention. Additionally, it's important to regularly clean and lubricate moving parts, as dust and debris can accumulate and hinder performance. By maintaining these components properly, operators can reduce wear and tear, ensuring that the press brake operates smoothly over time. Regular calibration of the machine can also help in achieving precise bending results, ultimately enhancing productivity in metalworking tasks.

Comparative Analysis of Hydraulic Press Brakes vs. Mechanical Press Brakes

When it comes to choosing the right pressing equipment for metalworking, understanding the difference between hydraulic press brakes and mechanical press brakes is crucial. Hydraulic press brakes utilize fluid power to generate force, allowing for significant bending capabilities and flexibility. According to industry reports, they offer a bending capacity of up to 1,000 tons and can easily accommodate varying material thicknesses, making them an ideal choice for complex operations. In contrast, mechanical press brakes operate with a direct drive system and are generally more suited for high-speed production and simple bends but may limit the versatility in handling thicker materials.

Tips: When selecting between hydraulic and mechanical press brakes, consider the specifics of your projects. If your work demands precision and the handling of diverse materials, hydraulic options may be more suitable. For high-volume production runs where speed is essential, mechanical press brakes can provide the necessary efficiency. Additionally, keep an eye on energy consumption; hydraulic brakes can sometimes result in higher operational costs due to the energy needed to pump fluids.

Ultimately, the decision boils down to the specific requirements of your metalwork operations. Both types have their unique benefits and potential drawbacks, so it's essential to evaluate factors like load capacity, bend accuracy, and production speed thoroughly. Invest time in understanding the full capabilities of each system to maximize your operational productivity.

Related Posts

-

Ultimate Guide to Choosing the Best Hydraulic Press Brake Machine for Your Needs

-

Unlock Precision and Reliability: Partner with China's Finest for Hydraulic Press Brake Solutions

-

Ultimate Guide to Mastering Metal Press Brake Operations for Precision Fabrication

-

Discover the Excellence of China's Leading Factory for the Best Small Press Brake Solutions Worldwide

-

Maximizing Precision and Efficiency in Fabrication with Advanced Sheet Metal Press Brake Technology

-

Craftsmanship Redefined Chinese Manufacturing Delivering the Best Press Brake Solutions Worldwide