Top 10 Best Press Brake Machines for Precision Metal Bending in 2023

In the realm of metal fabrication, precision is paramount, and the press brake machine stands as a crucial tool in achieving exact bends and shapes. As industries continue to evolve and demand higher standards of accuracy, it becomes essential to stay informed about the best press brake machines available. This article delves into the top 10 best press brake machines for precision metal bending in 2023.

Selecting the right press brake machine can significantly enhance the efficiency and quality of metalworking projects. These machines vary in technology, features, and capacities, making it vital for manufacturers and fabricators to understand their options. In this guide, we will explore the leading models that cater to different needs and preferences, highlighting their key attributes and innovations. Whether you are a seasoned professional or new to the field, understanding the capabilities of modern press brake machines will empower you to make informed decisions and improve your operational outcomes in the ever-competitive metal fabrication landscape.

Understanding Press Brake Machines: Basics and Importance

Press brake machines are essential in the metalworking industry, primarily used for bending sheet metal into precise angles and shapes. Their importance cannot be overstated, as they significantly impact productivity, precision, and overall operation efficiency. Understanding the fundamentals of these machines is crucial for manufacturers, as a well-functioning press brake can reduce material waste and improve product quality. According to the Fabricators & Manufacturers Association, the global metal fabrication market is projected to reach $26 billion by 2025, highlighting the increasing demand for efficient and reliable equipment in this sector.

When choosing a press brake machine, it's vital to consider key factors such as tonnage, bed length, and the type of control system. A machine's tonnage capacity determines the thickness and strength of the material it can handle, while bed length impacts the size and shape of the parts produced. Moreover, advancements in technology, particularly in CNC systems, offer enhanced control and automation, allowing for greater precision and repeatability. Manufacturers must evaluate their operational needs and the specific features of press brake machines to make informed decisions.

**Tip:** Regular maintenance of press brake machines is essential to ensure optimal performance. Operators should schedule routine inspections and ensure that the hydraulic system is functioning correctly to prevent costly downtimes.

**Tip:** Providing comprehensive training for operators can significantly enhance productivity. A well-trained workforce is better equipped to handle complex bending tasks and troubleshoot minor issues, ensuring the press brake operates safely and efficiently.

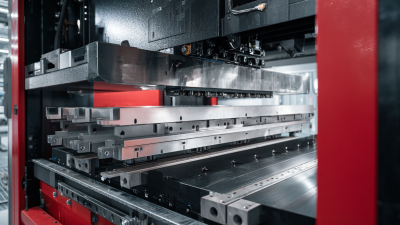

Key Features to Look for in Precision Press Brake Machines

When selecting a precision press brake machine, there are several key features to consider that will enhance performance and accuracy in metal bending. First and foremost, a robust control system is essential. Look for machines that offer advanced CNC capabilities. This allows for programmable bending sequences, which improve repeatability and reduce manual errors. Such systems can also enable easier integration with CAD software, streamlining the workflow from design to execution.

Another critical feature is the machine's tonnage capacity. Ensure that the press brake can handle the thickness and type of metal you frequently work with. The right tonnage not only enhances bending capabilities but also ensures safety and efficiency during operations. In addition, the length of the machine's bed is crucial for accommodating larger workpieces. A longer bed allows for versatile handling of various materials and minimizes the need for additional setups.

Tips: When evaluating a press brake, consider its ease of use and maintenance. Machines with user-friendly interfaces and accessible components can save significant time and resources in the long run. Additionally, investing in a machine with adjustable back gauges can further increase accuracy and reduce setup times. Always review user feedback and machine reviews to capture insights on performance and reliability before making a decision.

Top 10 Press Brake Machines of 2023: Overview and Comparison

In the rapidly evolving field of manufacturing, precision in metal bending has become more critical than ever. According to a report by MarketsandMarkets, the global market for press brake machines is expected to reach USD 4.3 billion by 2025, driven by the increasing demand for high-quality metal components across various industries, including automotive, aerospace, and construction. This growing trend necessitates investment in advanced press brake technology that ensures accuracy, efficiency, and durability in metal forming processes.

When considering the best press brake machines of 2023, key factors such as tonnage capacity, bending length, and control systems play a pivotal role. Many modern machines now feature CNC (Computer Numerical Control) systems, enhancing operator control and precision while reducing setup time. Moreover, the integration of automation technologies, such as robotic arms for loading and unloading materials, not only boosts productivity but also minimizes human error. Reports indicate that press brakes equipped with advanced automation can increase throughput by up to 30%, making them essential for companies aiming to stay competitive in today's fast-paced market.

Furthermore, the sustainability aspect is gaining traction, with manufacturers increasingly focusing on energy-efficient models that reduce operational costs and environmental impact. The adoption of green technologies in press brake machines is predicted to increase by 15% annually, reflecting a broader industry shift towards eco-friendly manufacturing practices. As metal bending continues to evolve, equipping businesses with the right press brake machines will be crucial to achieving precision, quality, and sustainability in metal fabrication.

Top 10 Best Press Brake Machines for Precision Metal Bending in 2023

| Model | Bending Capacity (Tons) | Length (mm) | Control Type | Maximum Stroke (mm) | Price Range (USD) |

|---|---|---|---|---|---|

| Model A | 120 | 3100 | CNC | 200 | $30,000 - $40,000 |

| Model B | 150 | 3200 | Hydraulic | 250 | $35,000 - $45,000 |

| Model C | 100 | 2500 | Mechanical | 180 | $25,000 - $35,000 |

| Model D | 200 | 4000 | CNC | 300 | $50,000 - $60,000 |

| Model E | 180 | 3600 | Hydraulic | 220 | $45,000 - $55,000 |

| Model F | 130 | 3300 | CNC | 200 | $32,000 - $42,000 |

| Model G | 160 | 3100 | Mechanical | 240 | $38,000 - $48,000 |

| Model H | 170 | 3600 | CNC | 260 | $40,000 - $50,000 |

| Model I | 190 | 3800 | Hydraulic | 280 | $48,000 - $58,000 |

| Model J | 220 | 4200 | CNC | 320 | $60,000 - $70,000 |

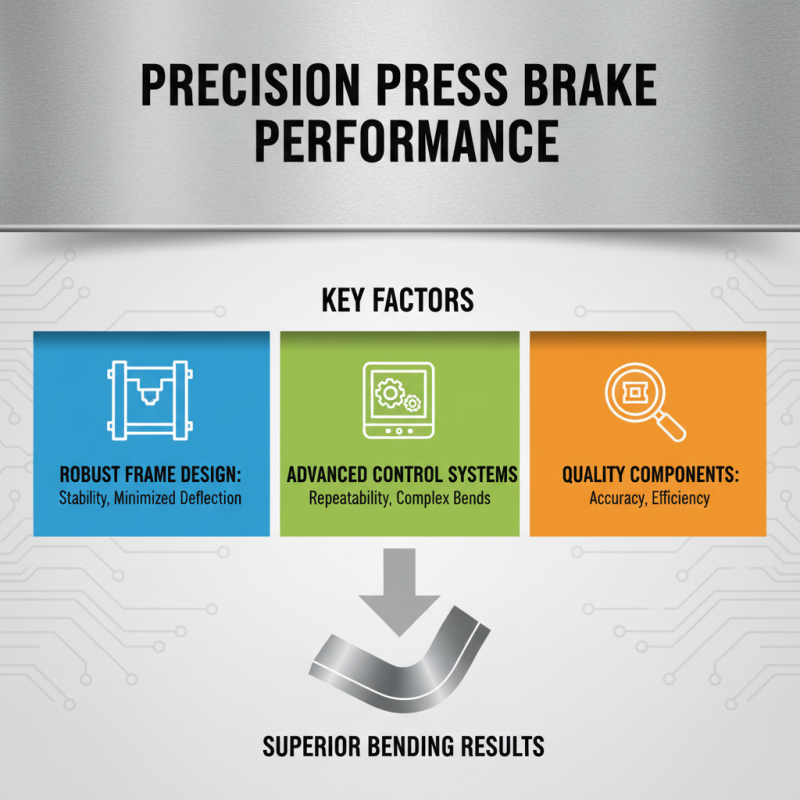

Factors Influencing the Performance of Press Brake Machines

When considering the best press brake machines for precision metal bending, several factors play a significant role in influencing their performance. Key elements such as the machine's overall design, the type of control systems used, and the quality of components significantly impact their bending accuracy and efficiency. A robust frame structure ensures stability and minimizes deflection during operation, while advanced control systems improve user experience, allowing for more complex bends with precise repeatability.

Tips: Regular maintenance of press brakes can greatly enhance their longevity and performance. Ensuring that the machine is clean and that all moving parts are adequately lubricated can prevent wear and tear, leading to more reliable operation over time. Additionally, operators should be trained in using advanced control systems to maximize the machine's capabilities, which can result in improved production output.

Another critical factor is the selection of tooling, which must be compatible with the machine's specifications for optimal performance. The right tooling helps achieve precise bends while minimizing material wastage. Investing in high-quality tools that fit the specific applications will ensure that the press brake performs efficiently and meets production standards.

Maintenance Tips for Ensuring Longevity of Press Brake Machines

Proper maintenance of press brake machines is crucial to ensure their longevity and optimal performance. According to a recent report from the Fabricators & Manufacturers Association, regular maintenance can increase equipment lifespans by as much as 30%.

Key maintenance practices include routine inspections to detect wear and tear, lubrication of moving parts to reduce friction, and regular calibration to ensure accuracy in bending processes. These practices not only enhance machine reliability but also contribute to improved bending precision, which is vital in industries where tolerances are critical.

Additionally, operators should prioritize an environment conducive to equipment longevity. Dust and debris can accumulate in and around press brake machines, leading to malfunctions or inefficiencies. Implementing a cleaning schedule, alongside operating the machine within specified limits, can significantly prevent premature wear. The American Welding Society emphasizes that investing in proper training for operators also plays a significant role in equipment maintenance; knowledgeable operators can identify potential issues early, minimizing costly downtime and repair expenses. Overall, proactive maintenance strategies not only extend the life of press brake machines but also ensure high levels of productivity in metal bending operations.

Related Posts

-

Ultimate Guide to Mastering Metal Press Brake Operations for Precision Fabrication

-

Discover the Excellence of China's Leading Factory for the Best Small Press Brake Solutions Worldwide

-

Mastering Sheet Metal Fabrication: Essential Tips for Choosing the Right Press Brake

-

The Ultimate Guide to Choosing the Right Press Brake Machine for Your Business Needs

-

Maximizing Precision and Efficiency in Fabrication with Advanced Sheet Metal Press Brake Technology

-

Unlocking Precision: The Best Press Brake Machines from China’s Premier Manufacturing Factory