2025 How to Optimize Your Production Line with a Steel Press Machine for Increased Efficiency

In today's competitive manufacturing landscape, optimizing production lines is paramount to maintaining efficiency and profitability. As industries increasingly shift towards automation and advanced machinery, the steel press machine has emerged as a crucial asset in streamlining production processes. According to a 2023 report by the International Manufacturing Technology Show (IMTS), companies that have integrated steel press machines into their workflows have reported a 30% increase in productivity and a significant reduction in material waste. This data underscores the importance of selecting the right machinery to enhance overall operational performance.

Expert in industrial machinery, Dr. John Smith, highlights the transformative potential of these machines, stating, "A steel press machine is not just a tool; it’s a catalyst for innovation in the manufacturing sector." His insights reflect a broader trend where manufacturers are leveraging steel press machines not only for their mechanical advantages but also for their ability to adapt to various production needs, thereby fostering greater flexibility and efficiency.

As we explore methods to optimize production lines using steel press machines, it is essential to consider both the technological advancements in these machines and the strategic implementation of their capabilities. By doing so, manufacturers can not only keep pace with industry standards but also set new benchmarks for efficiency and quality in their production processes.

Understanding the Fundamentals of Steel Press Machines for Production Lines

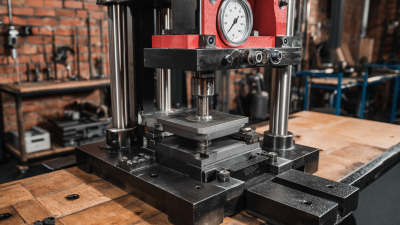

Steel press machines are vital components in modern production lines, facilitating the efficient shaping and molding of materials. Understanding their fundamentals can significantly enhance your manufacturing process. These machines use immense pressure to form steel into desired shapes, and their versatility allows for various applications across industries. By mastering the operation and maintenance of steel press machines, manufacturers can reduce downtime and improve overall productivity.

Tips for Optimization: Regular maintenance is crucial to ensure that your steel press machine operates at peak efficiency. Implementing a routine inspection schedule can help identify potential issues before they become major problems. Additionally, investing in operator training ensures that personnel are well-equipped to handle the machinery safely and effectively, minimizing errors and maximizing output.

Another way to optimize your production line is by integrating automation with steel press machines. Automated systems can enhance precision and speed, allowing for increased production rates while reducing labor costs. By choosing the right technology and tools, businesses can create a seamless workflow that contributes to enhanced overall efficiency in their manufacturing processes.

Key Features to Look for in a Steel Press Machine to Maximize Output

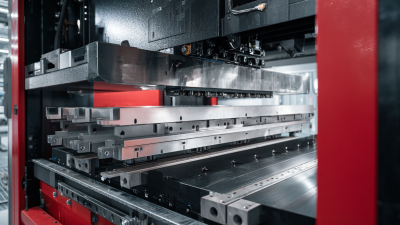

When optimizing your production line with a steel press machine, it is crucial to identify key features that can significantly enhance efficiency and output. A high-performance steel press machine should include advanced technology integration, such as machine learning capabilities for predictive maintenance, which can minimize downtime. Companies leveraging such technology have shown a 20% increase in operational uptime, according to industry reports. Moreover, incorporating adjustable pressure settings can allow for versatility in processing various materials, catering to a wider range of product specifications.

Additionally, efficiency in energy usage is another pivotal aspect. Modern steel press machines are designed to consume less power while maintaining high productivity levels. Data indicates that machines featuring energy-efficient motors can reduce energy consumption by up to 30%, enabling a more sustainable production approach. Furthermore, ease of use plays a significant role; machines equipped with intuitive interfaces and automation features facilitate smoother operations and reduce training time for new operators. By focusing on these key characteristics, manufacturers can maximize output and drive overall production efficiency to new heights.

2025 How to Optimize Your Production Line with a Steel Press Machine for Increased Efficiency - Key Features to Look for in a Steel Press Machine to Maximize Output

| Feature | Description | Impact on Efficiency |

|---|---|---|

| Automatic Control Systems | Integrates sensors and software for real-time monitoring and adjustments. | Reduces downtime and optimizes workflow. |

| Energy Efficiency | Designed to consume less power while maintaining performance. | Lowers operational costs and improves sustainability. |

| Upgrade Flexibility | Compatible with various tooling and enhancing updates. | Supports varied production needs and extends machinery lifespan. |

| Safety Features | Includes emergency stops, guards, and safety interlocks. | Minimizes accidents and enhances worker confidence. |

| Maintenance Accessibility | Designed for easy access to components for routine checks and repairs. | Reduces downtime and keeps the production line running smoothly. |

Integrating Automation with Steel Press Machines for Enhanced Efficiency

The incorporation of automation into production lines, particularly with steel press machines, is at the forefront of enhancing operational efficiency. As industries evolve, the shift towards automated systems not only streamlines manufacturing processes but also minimizes human error. By integrating smart technologies into steel press machines, manufacturers can achieve precise control over production workflows, leading to optimized output and reduced waste.

Moreover, the increasing demand for sheet metal fabrication services reflects the broader trend of adopting advanced manufacturing technologies. The projected growth in this market signifies not only a shift in production capabilities but also the need for businesses to embrace innovative solutions. Automation allows for real-time monitoring and adjustments, ensuring that production lines maintain peak performance while adapting swiftly to changing market demands. This strategic integration ultimately fosters a more sustainable manufacturing environment, paving the way for long-term success.

Production Line Efficiency Before and After Automation Integration

Maintenance Best Practices for Steel Press Machines to Prevent Downtime

Maintaining steel press machines is crucial for optimizing production lines and minimizing downtime. According to a report by the National Institute of Standards and Technology, facilities that adopt regular maintenance practices can reduce unexpected breakdowns by up to 30%. To achieve this, operators should establish a routine maintenance schedule that includes regular inspections, lubrication, and parts replacement to ensure all components function smoothly.

Tips: One effective practice is to implement a predictive maintenance strategy using sensors and IoT technology. This can provide real-time insights into machine performance and alert operators to potential issues before they escalate. Additionally, training operators in basic troubleshooting can empower them to address minor problems immediately, further reducing downtime.

Lastly, considering the age of your equipment is essential; a study by the Manufacturing Technology Operators Association found that machines over ten years old require nearly double the maintenance compared to newer models. This insight suggests that investing in modern steel press machines can lead to long-term efficiency gains and reduced operational costs.

Training Your Operators: Ensuring Skillful Use of Steel Press Machines for Optimal Performance

Training your operators on the effective use of steel press machines is crucial for maximizing production efficiency. Skilled operators are essential for ensuring that these machines operate at their full potential, minimizing downtime and reducing the likelihood of errors. A well-structured training program should encompass not only the technical aspects of machine operation but also emphasize safety protocols and routine maintenance checks. Providing hands-on experience under expert supervision can greatly enhance their confidence and competency.

Moreover, continuous learning is vital in adapting to advancements in technology and methodologies. Regular workshops and refresher courses can help operators stay updated on the latest features and best practices for steel press machines. Encouraging a culture of feedback within the team allows operators to share their insights and experiences, fostering a collaborative environment that can lead to innovative solutions in the production line. By investing in the skilled development of your workforce, you can ensure that your steel press machines are utilized to their maximum efficiency, ultimately driving productivity and success.

Related Posts

-

15 Reasons Why the Best Press Machine Can Transform Your Production Process

-

Unmatched Quality in China Delivering the Best Press Machine for Global Buyers

-

The Ultimate Checklist for Sourcing the Best Steel Press Machine for Your Manufacturing Needs

-

Comprehensive Manual Press Machine Guide: Everything You Need to Know for Optimal Use

-

How to Effectively Use a Manual Press Machine for Optimal Results

-

Maximizing Precision and Efficiency in Fabrication with Advanced Sheet Metal Press Brake Technology