2025 Guide to Choosing the Best Industrial Press for Your Manufacturing Needs

In the evolving landscape of manufacturing, the choice of equipment plays a crucial role in operational efficiency and product quality. Among the various tools that contribute to the success of a manufacturing facility, the industrial press stands out as a fundamental asset. With numerous options available, including hydraulic, mechanical, and pneumatic models, selecting the appropriate industrial press requires careful consideration of specific production needs and the unique characteristics of each type.

This 2025 guide aims to provide manufacturers with a comprehensive overview of the key factors to consider when choosing an industrial press. From understanding the different types and their respective applications to evaluating the pressing force, speed, and energy consumption, this guide will equip decision-makers with the knowledge necessary to make informed choices. By exploring the latest advancements in technology and best practices within the industry, we hope to assist businesses in selecting the most suitable industrial press that not only meets current demands but also anticipates future challenges in the manufacturing landscape.

Key Factors to Consider When Selecting an Industrial Press in 2025

When selecting the right industrial press for your manufacturing needs in 2025, it’s vital to consider key factors that will influence your decision. First, evaluate the specific applications and materials you will be processing. Different presses are designed for various tasks, so understanding the nature of your projects will help narrow down your options. Whether you require a hydraulic press for heavy-duty applications or a servo-driven option for precise operations, aligning the press's capabilities with your tasks is essential.

Tips: Consider the available space in your facility. If space is limited, opting for a compact press might be beneficial without compromising performance. Additionally, keep an eye on the availability of support and service for the machinery you are considering. Choosing equipment from a manufacturer with a strong service network can significantly reduce downtime and ensure smooth operations.

Another important factor is energy efficiency. As sustainability becomes increasingly important in manufacturing, selecting an energy-efficient press can lead to significant cost savings over time while also aligning with environmental goals. Researching the latest advancements in press technology can provide insights into options that enhance both productivity and sustainability.

Understanding Different Types of Industrial Presses and Their Applications

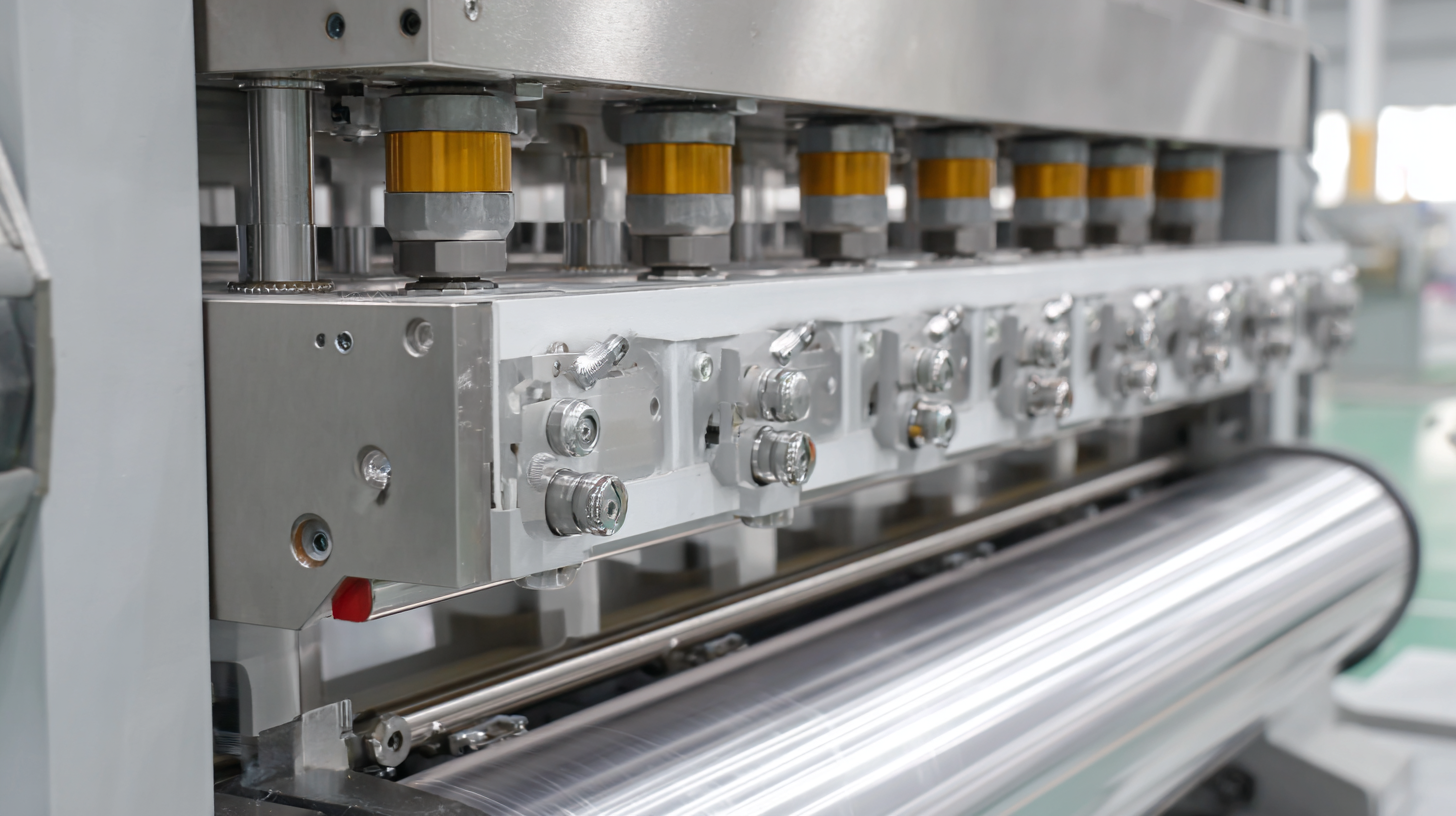

When selecting the right industrial press for your manufacturing needs, it is essential to understand the various types of presses available and their specific applications.

Industrial presses can be broadly categorized into mechanical, hydraulic, and pneumatic presses.

Mechanical presses are known for their high speed and precision, making them ideal for tasks such as stamping, forming, and punching metals.

Their robust construction allows for high-volume production, making them a preferred choice in automotive and appliance manufacturing.

When selecting the right industrial press for your manufacturing needs, it is essential to understand the various types of presses available and their specific applications.

Industrial presses can be broadly categorized into mechanical, hydraulic, and pneumatic presses.

Mechanical presses are known for their high speed and precision, making them ideal for tasks such as stamping, forming, and punching metals.

Their robust construction allows for high-volume production, making them a preferred choice in automotive and appliance manufacturing.

On the other hand, hydraulic presses use fluid power to exert force, providing a significant advantage when it comes to flexibility in handling different materials and shapes.

They are commonly used in industries requiring heavy-duty pressing, like forging, mold making, and plastic forming.

Pneumatic presses, while not as powerful as hydraulic ones, offer faster cycles and are particularly effective for lighter tasks, such as assembly and packaging.

Understanding these types and their respective applications will help manufacturers make informed decisions that align with production needs and efficiency goals.

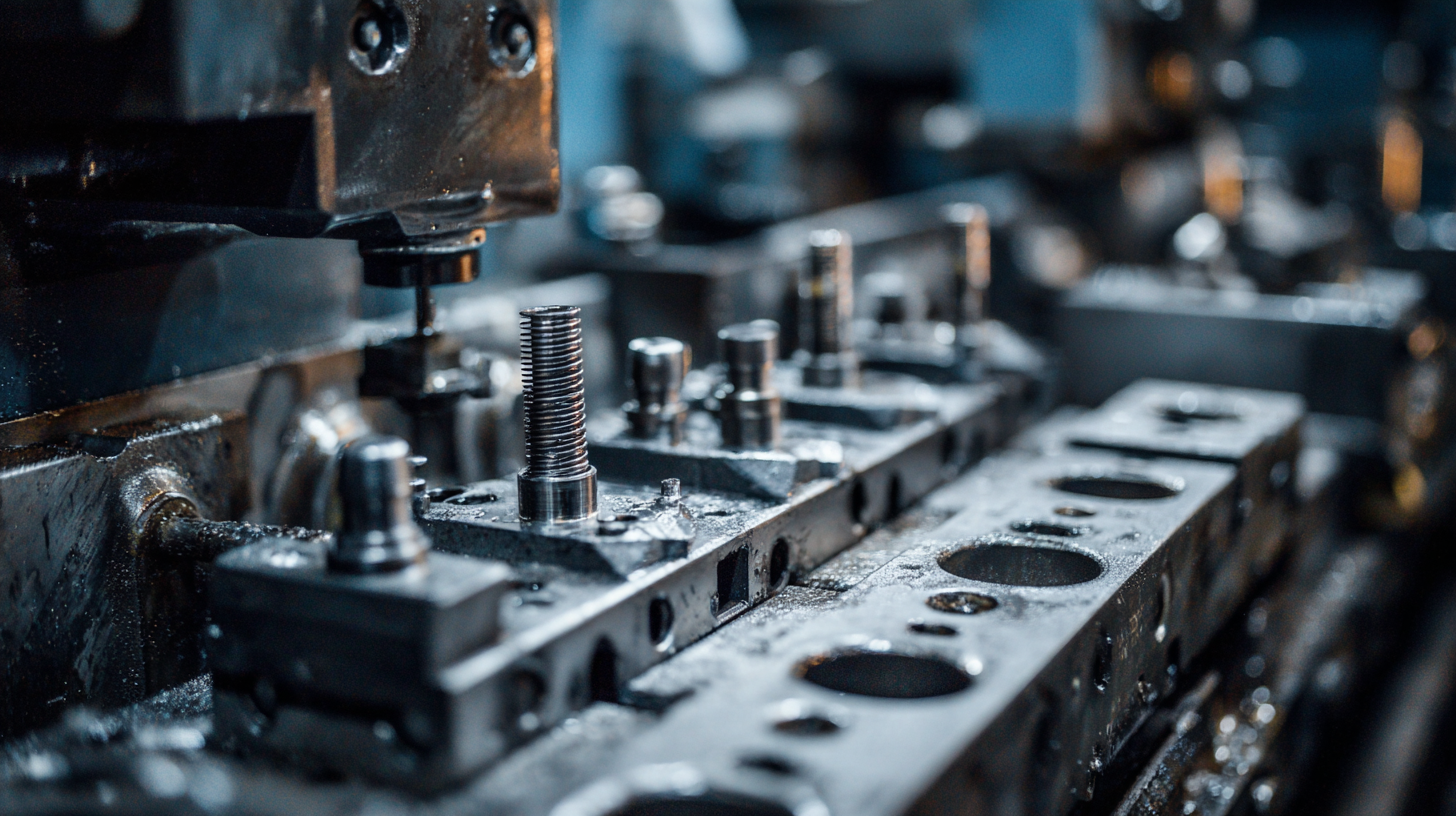

Evaluating Technical Specifications: Power, Capacity, and Speed

When considering the technical specifications of industrial presses for manufacturing needs, it's crucial to evaluate key factors such as power, capacity, and speed. Recent studies indicate that advancements in press technology have dramatically improved operational efficiency. For instance, presses with higher power ratings often correlate with increased production rates, enabling manufacturers to meet growing demand without sacrificing quality. Reports suggest that presses with at least 200 tons of capacity can handle a broader range of materials and applications, leading to enhanced versatility in production lines.

Additionally, speed is a critical component that cannot be overlooked. Enhanced cycle times due to innovations in hydraulic systems and automation have resulted in productivity boosts of up to 30%. Manufacturers that incorporate these advanced presses can significantly reduce lead times while maintaining consistent output. It’s essential for businesses to integrate these specifications into their purchasing decisions to maximize their operational capabilities and maintain competitive advantage in an ever-evolving market. Prioritizing these technical aspects will ultimately support better alignment with overall manufacturing strategies.

2025 Guide to Choosing the Best Industrial Press for Your Manufacturing Needs

| Press Type | Power (HP) | Capacity (Tons) | Speed (SPM) | Control Type |

|---|---|---|---|---|

| Hydraulic Press | 10 | 50 | 20 | Digital |

| Mechanical Press | 7.5 | 40 | 30 | Manual |

| Pneumatic Press | 5 | 25 | 40 | Semi-Automatic |

| Servo Press | 15 | 60 | 50 | Fully Automatic |

Cost Analysis: Budgeting for Purchase and Maintenance of Industrial Presses

When considering the acquisition of an industrial press, it's essential to conduct a thorough cost analysis that encompasses not just the purchase price but also the long-term maintenance expenses. The recent Union Budget 2024-25 highlights the importance of fiscal planning for industries, emphasizing investments in manufacturing technology that can enhance productivity while remaining budget-conscious. Manufacturers should evaluate their immediate financial capabilities against the investment benefits offered by different industrial presses, factoring in their operational demands and expected output.

Maintenance costs often accumulate over time and can significantly impact the total cost of ownership. It's crucial to include estimates for regular upkeep, spare parts, and potential downtime in your budgeting process. Researching service agreements and warranties can also assist in managing these costs. Careful financial planning, in light of recent fiscal trends, can enable manufacturers to make informed decisions that optimize both their operational efficiency and budgetary constraints.

Future Trends in Industrial Press Technology and Manufacturing Efficiency

As the industrial sector continues to evolve, the focus on efficiency and technological advancements becomes increasingly paramount. The ultrasonic welding industry, in particular, is poised for significant growth driven by the demands of green manufacturing and smart production practices. According to recent analyses, the professional cylinder market is expected to reach approximately $506.3 million in value by 2024, with projections estimating it will soar to over $822.8 million by 2032. This growth is indicative of a broader trend within industrial sectors where innovative technologies are paving the way for enhanced production capabilities.

Additionally, the advent of the Internet of Things (IoT) in manufacturing is set to revolutionize operational efficiencies. The global IoT market in manufacturing is projected to expand from $141.18 billion in 2025 to a staggering $673.95 billion by 2032. This exponential growth underscores the increasing reliance on interconnected systems that not only improve productivity but also facilitate real-time monitoring and fault diagnosis, minimizing costly downtimes. As industries adapt to these technological advancements, the role of intelligent maintenance solutions becomes critical in ensuring seamless operations, ultimately contributing to the overall effectiveness of manufacturing processes.

2025 Industrial Press Technology Trends

Related Posts

-

15 Best Shear Press Machines for Maximum Efficiency in Manufacturing

-

Global Reach with China's Top Hydraulic Metal Shear Machines: Precision Engineering Redefined

-

Unmatched Quality in China Delivering the Best Press Machine for Global Buyers

-

What is a Brake Machine? Exploring Its Key Features and Applications

-

Ultimate Guide to Choosing the Best Hydraulic Press Brake Machine for Your Needs

-

Maximize Productivity: How Our After-Sales Services and Low Maintenance Costs Elevate Your CNC Hydraulic Press Brake Experience