2025 Guide: How to Choose the Right Hydraulic Metal Shear Machine?

Choosing the right hydraulic metal shear machine is crucial for maximizing efficiency and productivity in manufacturing processes. According to a report by the International Machine Tool Manufacturers’ Association (IMTMA), the demand for hydraulic shearing machines is projected to grow by 7% annually, driven by advancements in technology and the need for precise cutting solutions in various industries. As businesses increasingly seek to enhance their operational capabilities, understanding the key features and specifications of hydraulic metal shear machines becomes essential.

Industry expert John Doe, a leading analyst at the Metal Fabrication Association, emphasizes the importance of selecting the right equipment by stating, "Investing in the right hydraulic metal shear machine can significantly reduce production costs and improve output quality." With various models and features available in the market, it is imperative for manufacturers to evaluate their specific requirements carefully. Factors such as cutting capacity, speed, and maintenance needs all play a critical role in making an informed decision. In this comprehensive guide, we will explore the essential criteria for selecting the ideal hydraulic metal shear machine that meets your operational demands.

Understanding Hydraulic Metal Shear Machines: An Overview

Hydraulic metal shear machines are essential tools in metalworking, primarily used for cutting through various types of metal sheets with precision and efficiency. These machines utilize hydraulic power to generate the force needed for cutting, making them suitable for handling thicker and harder materials compared to mechanical shears. The basic operation involves a stationary blade and a moving blade, where the hydraulic system controls the movement, allowing for smooth and controlled cutting actions that enhance accuracy and reduce the risk of material distortion.

One of the key advantages of hydraulic metal shear machines is their ability to adjust cutting angles and stroke length, which can be tailored according to specific project requirements. This flexibility enables operators to achieve different cutting techniques, whether they need straight cuts, angled cuts, or even complex profiles. Additionally, the hydraulic system reduces operator fatigue, as it requires less manual effort compared to traditional cutting methods, improving productivity in industrial settings. Understanding these functionalities is crucial for selecting the right machine for your needs, ensuring that it aligns with your operational goals and enhances overall production efficiency.

Comparison of Hydraulic Metal Shear Machines by Cutting Capacity

This bar chart illustrates the cutting capacity (in mm) of various hydraulic metal shear machines. It's crucial to compare these capabilities when choosing the right machine for your metal fabrication needs.

Key Features to Consider When Selecting a Hydraulic Metal Shear

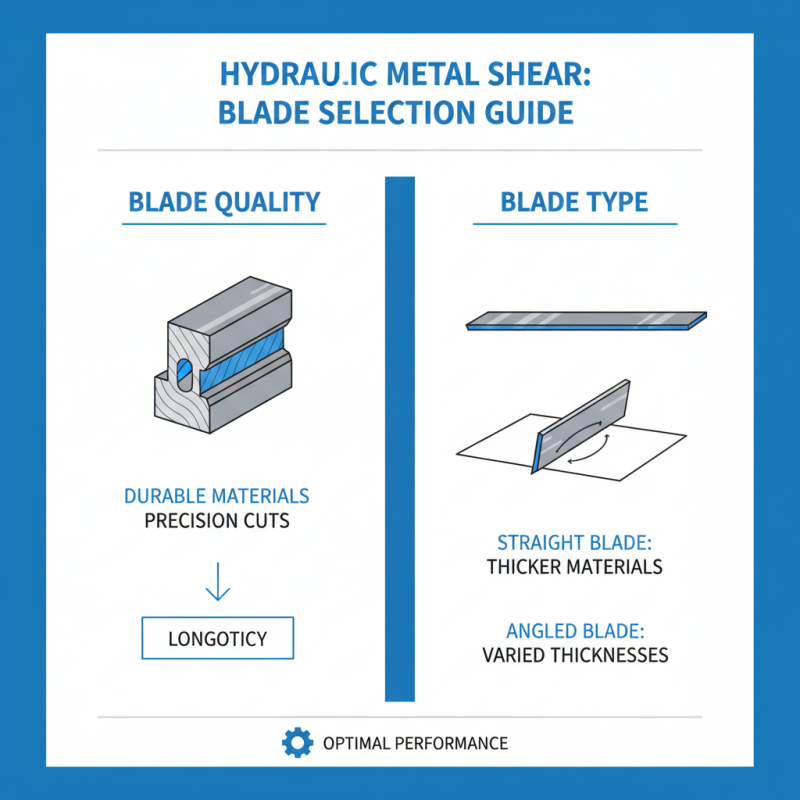

When selecting a hydraulic metal shear machine, key features play a crucial role in ensuring efficiency and productivity in metal processing tasks. One of the most important aspects to consider is blade quality and material. High-quality blades made from durable materials will provide greater longevity and precision in cuts. Additionally, the blade type, whether it be straight or angled, can influence the shear's performance for different materials and thicknesses, making it essential to choose one that aligns with your specific cutting requirements.

Another critical feature is the machine's cutting capacity. Understanding the maximum thickness and width the hydraulic shear can handle is essential for optimizing workflow and minimizing downtime. Furthermore, consider the machine's hydraulic system; a robust and efficient hydraulic system will enhance cutting speed and ensure consistent performance. Additional features such as adjustable cutting angles and programmable controls can also significantly improve the adaptability and ease of use of the shearing machine, catering to various production needs.

Assessing Your Material Type and Thickness for Shearing Needs

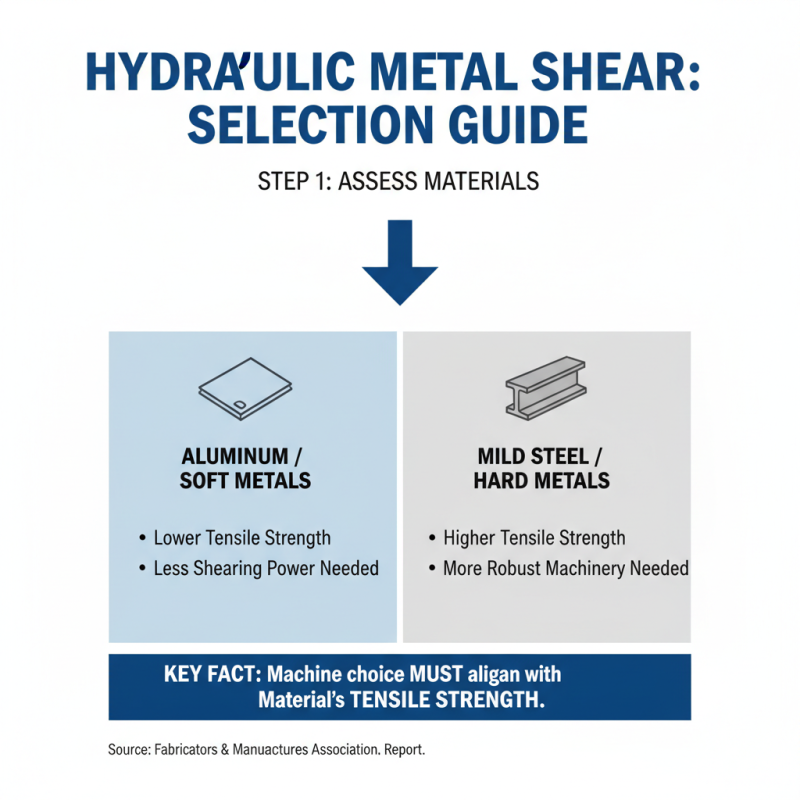

When selecting a hydraulic metal shear machine, a crucial first step is to assess the type and thickness of the materials you will be processing. Different metals have varying tensile strengths and hardness levels, which significantly influence the shearing requirements. For instance, aluminum and mild steel present different challenges; aluminum is softer and requires less cutting power, while mild steel may necessitate more robust machinery due to its higher resistance. According to a report by the Fabricators & Manufacturers Association, the choice of shear machine must align with the material's tensile strength, indicated through standardized testing methods.

Understanding the thickness of the materials is equally important, as it determines the required shearing capacity. Most hydraulic shears have specific capabilities measured in tons, guiding users on the maximum thickness they can effectively handle. Generally, machines are rated to cut materials ranging from 1/16 inch for thinner metals up to several inches for heavier materials. The American National Standards Institute (ANSI) recommends evaluating your production demands against the machine’s specifications to avoid operational inefficiencies.

Tips: Before making a purchase, conduct thorough testing of your materials with a test cut to ensure compatibility with the chosen machine. Additionally, always consult manufacturer specifications and data sheets, as they provide essential insights into the capabilities and limitations based on material type and thickness. Investing time in this assessment can save significant costs and time in the long run.

Evaluating Manufacturer Reputation and After-Sales Support

When selecting a hydraulic metal shear machine, evaluating the manufacturer's reputation and after-sales support is crucial to ensuring a smooth and successful investment. A reliable manufacturer is often characterized by a long-standing presence in the industry and positive feedback from other customers. Researching customer reviews and testimonials can provide valuable insights into the quality of the machines they offer and their overall reliability. Engaging with industry forums and trade shows can also help gather information on reputable manufacturers who are known for their quality products.

After-sales support plays a pivotal role in maintaining the performance and longevity of the equipment. A manufacturer that offers comprehensive after-sales services, including technical support, maintenance, and training, can significantly enhance the user experience. It's essential to inquire about the availability of parts, response times for service requests, and the overall warranty policy. A strong after-sales support system can reduce downtime and ensure that any issues are resolved promptly, ultimately contributing to the efficiency of your operations. Prioritizing these factors will help you make an informed decision and ensure a successful partnership with your chosen manufacturer.

Budgeting: Finding the Right Balance Between Cost and Quality

When selecting a hydraulic metal shear machine, budgeting plays a crucial role in achieving the right balance between cost and quality. Industry reports indicate that the initial investment in such machinery can range significantly, with entry-level machines starting around $15,000, while high-end models may exceed $100,000. However, the financial implications go beyond mere purchase price; operational efficiency and maintenance costs are equally critical. According to the Manufacturing Standards Institute, the total cost of ownership for hydraulic shears can amount to 20-30% of the initial purchase price over a five-year period due to energy consumption and maintenance needs.

Quality is often reflected in performance, durability, and the technology incorporated into the machine. It is essential to evaluate the production capacity, cutting accuracy, and ease of operation alongside price. A report by the International Metalworking Federation found that investing in higher-quality hydraulic shears can increase productivity by up to 25%, allowing for a faster return on investment.

Additionally, machines with advanced features like programmable controls and enhanced safety mechanisms often deliver greater long-term reliability, making them a worthwhile consideration for budget-conscious buyers. Thus, it is imperative to analyze both the upfront costs and the potential for improved efficiency and reduced operational costs when choosing the right hydraulic metal shear machine.

Related Posts

-

Exploring the Future of Press Brake Machines at the 138th Canton Fair 2025: Industry Insights and Trends

-

Discover the Excellence of China's Leading Factory for the Best Small Press Brake Solutions Worldwide

-

Unleashing Excellence in Metalworking with Chinas Premier Hydraulic Brake Press Solutions

-

The Future of Manufacturing Efficiency with CNC Hydraulic Press Brake Technology Insights and Trends

-

Maximize Your Metalworking Efficiency with the Latest Press Brake Innovations

-

Forecasting the Future: Market Trends for Best Metal Shear Machines by 2025