Maximize Your Metalworking Efficiency with the Latest Press Brake Innovations

In the rapidly evolving landscape of metalworking, the efficiency of manufacturing processes is paramount. Among the essential tools in this industry, the press brake stands out as a vital instrument for precision bending and forming metal components. According to the latest market research report by Grand View Research, the global press brake market is expected to reach USD 4.6 billion by 2027, growing at a compound annual growth rate (CAGR) of 5.2%. This growth is driven by the increasing demand for automation and high precision in metal fabrication. Innovations in press brake technology, such as advancements in CNC systems and hybrid models, are setting new standards for productivity and accuracy. By leveraging these latest innovations, manufacturers can significantly enhance their operational efficiency, reduce waste, and improve the quality of their products. Understanding these developments is essential for companies aiming to stay competitive in the dynamic metalworking industry.

Understanding the Basics of Press Brakes in Metalworking

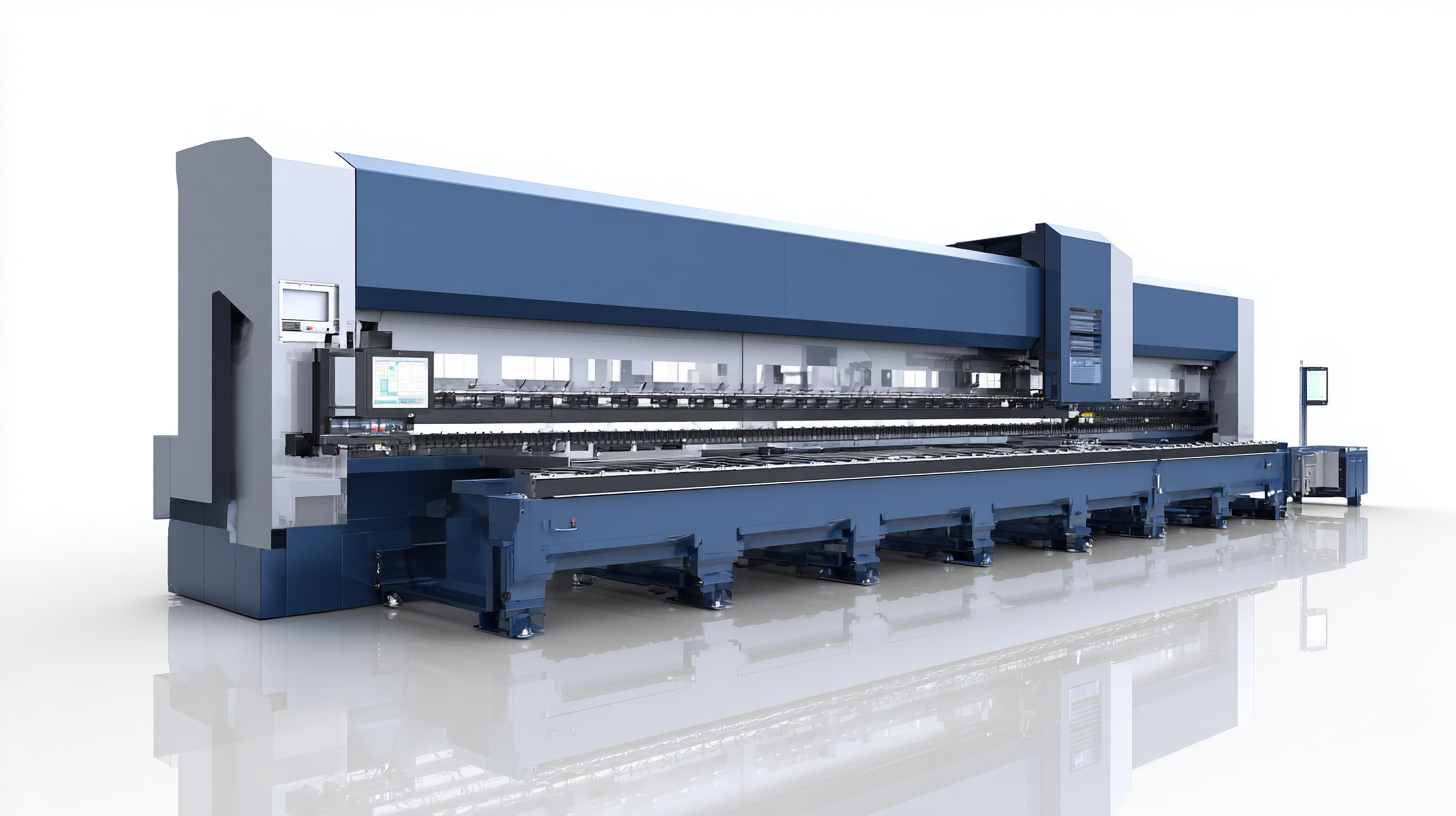

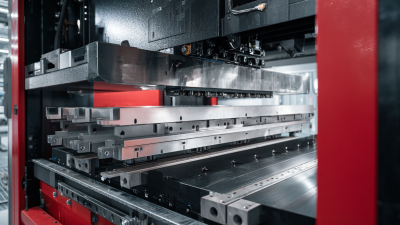

Press brakes are essential tools in metalworking, allowing for precise bending and shaping of metal sheets. Understanding how they function is crucial for maximizing their efficiency and effectiveness in any fabrication shop. At their core, press brakes operate by applying localized pressure to a metal workpiece through a corresponding die and punch system. This process transforms flat metal sheets into various shapes required for different applications, from enclosures to structural components.

With advancements in technology, modern press brakes have integrated features that enhance performance and ease of use. For instance, CNC-controlled press brakes offer increased accuracy and repeatability, minimizing human error during operation. Operators can input complex bending sequences and receive real-time feedback, allowing for intricate designs and faster production times. As metalworking continues to evolve, staying informed about the latest innovations in press brake technology is essential for improving workflow and achieving high-quality results in metal fabrication.

Key Innovations Transforming Press Brake Technology Today

The landscape of press brake technology is undergoing significant transformations, ushered in by a wave of innovative advancements. These changes are critical for manufacturers aiming to enhance their operational efficiency and precision in metalworking. Notable innovations include the integration of advanced automation systems, which allow for greater accuracy and reduced cycle times. Enhanced software algorithms now enable real-time monitoring and machine learning, optimizing processes and minimizing errors during the bending operations.

Furthermore, recent developments in energy-efficient hydraulic systems are setting new standards for sustainability in manufacturing. This shift not only reduces operational costs but also aligns with global efforts toward greener production methods. As manufacturers continue to adopt these cutting-edge technologies, the opportunity to maximize productivity while maintaining high-quality standards becomes increasingly attainable, ensuring competitiveness in a fast-evolving industry.

Enhancing Precision and Speed with Advanced Press Brake Features

The advanced features of modern press brakes are revolutionizing metalworking processes, significantly enhancing both precision and speed. Innovations such as adaptive learning systems and advanced sensor technology allow machines to continuously adjust to varying material properties, ensuring optimal performance during each bend. These features minimize the risk of error and reduce material waste, leading to more cost-effective production cycles.

Furthermore, the incorporation of sophisticated software solutions enables operators to simulate bending processes and anticipate challenges before actual fabrication begins. This not only accelerates setup times but also enhances the accuracy of complex parts. With real-time data analysis and reporting capabilities, fabricators can monitor performance and make immediate adjustments, driving efficiency to new heights. Thus, embracing these cutting-edge press brake technologies is essential for businesses aiming to remain competitive in a fast-paced manufacturing landscape.

Maximize Your Metalworking Efficiency with Advanced Press Brake Features

Integrating Automation for Greater Efficiency in Metalworking

In the fast-paced world of metalworking, integrating automation into processes such as press braking is becoming essential for maximizing efficiency. According to a recent report by the International Federation of Robotics, the global market for industrial robots is projected to grow at a compound annual growth rate (CAGR) of 26% through 2024. This surge is indicative of how automation can significantly enhance productivity in metalworking operations.

By adopting automated press brake systems, manufacturers can reduce cycle times and minimize human error, leading to higher quality outcomes. According to a study published by the Fabricators & Manufacturers Association, companies that implement automation in their press brake operations report a productivity increase of up to 30%. Furthermore, automation not only streamlines labor-intensive tasks but also optimizes material usage, with some manufacturers achieving up to a 15% reduction in waste through precise automated controls.

The integration of advanced technologies such as machine learning and IoT in press brakes can drive even greater efficiencies. A report by McKinsey highlights that companies leveraging IoT solutions can enhance their operational efficiency by up to 20%, allowing for real-time monitoring and predictive maintenance. Such innovations are critical in establishing a competitive edge in the metalworking sector, underscoring the importance of embracing automation as a pivotal strategy for future growth.

Maximize Your Metalworking Efficiency with the Latest Press Brake Innovations - Integrating Automation for Greater Efficiency in Metalworking

| Feature | Description | Benefits | Impact on Efficiency |

|---|---|---|---|

| Automation | Integration of automated systems for precision operations. | Reduces operational errors, improves speed. | Increases production rates by up to 40%. |

| Smart Controls | Advanced control systems for better handling of processes. | Enhances quality of output, reduces scrap. | Improves material utilization by 15%. |

| Data Analytics | Utilization of big data for process optimization. | Informs decision-making, predictive maintenance. | Reduces downtime by 20%. |

| User Interfaces | Intuitive dashboards and touch displays. | Improves user experience, reduces training time. | Enhances user efficiency by 30%. |

| Energy Efficiency | Sustainable energy options and low power consumption. | Reduces operational costs, environmentally friendly. | Lowers energy use by 25%. |

Best Practices for Implementing New Press Brake Innovations in Your Shop

To effectively implement new press brake innovations in your shop, start by conducting a thorough assessment of your current operations. Identify specific areas where efficiency could be improved, such as cycle times, material handling, and worker ergonomics. Understanding these baseline metrics will help you measure the impact of any new technology. Engage your team in discussions about the innovations to gather insights and foster a culture of collaboration, as their hands-on experience can illuminate practical challenges that may arise during implementation.

Once you’ve selected the appropriate innovations, invest in training to equip your operators with the necessary skills. Hands-on workshops or simulations can enhance their understanding of the new systems and technologies, significantly reducing the learning curve. Additionally, consider creating a pilot program where new tools and techniques can be tested in a controlled environment. This approach allows for troubleshooting and fine-tuning before a full rollout, ensuring that your shop is prepared to maximize productivity while minimizing disruptions. Remember, integrating innovation is not just about technology; it's about empowering your workforce to adapt and excel.

Related Posts

-

Discover the Advantages of Choosing the Best Press Brake for Your Manufacturing Needs

-

The Future of Precision Engineering with Best Press Brake Technology

-

Maximizing Precision and Efficiency in Fabrication with Advanced Sheet Metal Press Brake Technology

-

Why Small Press Brakes Are Essential for Precision Metal Bending in Modern Manufacturing

-

Exploring the Future of Press Brake Machines at the 138th Canton Fair 2025: Industry Insights and Trends

-

Why Understanding Hydraulic Press Brakes is Essential for Modern Manufacturing