The Ultimate Guide to Choosing the Right Press Brake Machine for Your Business Needs

In the ever-evolving landscape of manufacturing, selecting the right press brake machine is critical for businesses aiming to enhance their productivity and operational efficiency. According to a recent report by IBISWorld, the metal forming machinery manufacturing sector is poised to grow at an annual rate of 3.5%, underlining the importance of investing in advanced press brake technology to stay competitive. With a variety of options available, from mechanical to hydraulic systems, making an informed choice can significantly impact a company’s ability to meet demanding production schedules and intricate design requirements. Understanding the specific needs of your business, alongside emerging industry trends, is essential to selecting a press brake machine that not only meets current demands but also accommodates future expansions and innovations.

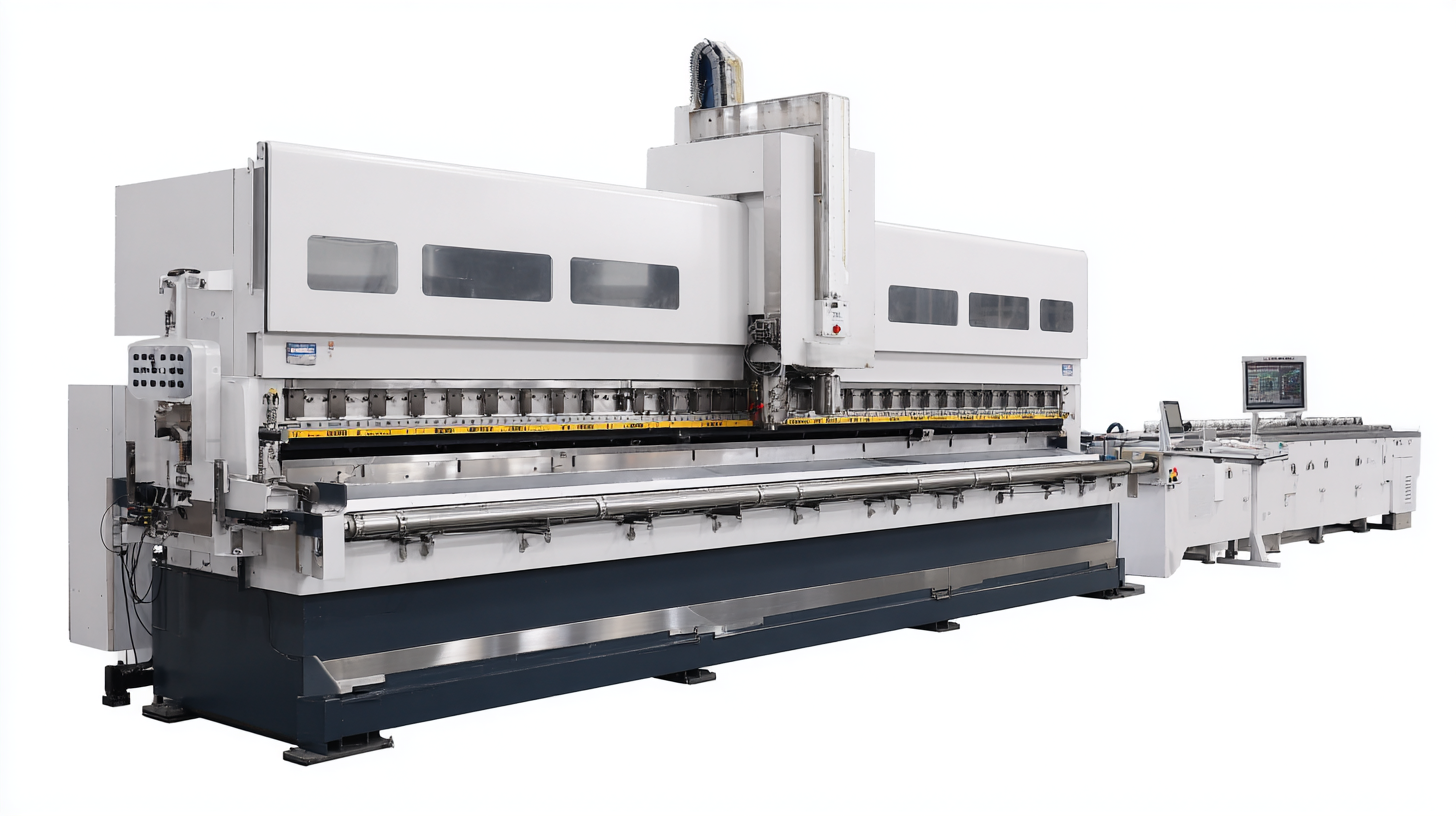

Understanding the Different Types of Press Brake Machines Available in the Market

When selecting the right press brake machine for your business needs, it's crucial to understand the various types available on the market. Press brakes are primarily categorized into mechanical, hydraulic, and servo-electric types.

Mechanical press brakes use a flywheel and crank system, ideal for high-speed operations but limited in flexibility. Hydraulic press brakes utilize hydraulic fluid to generate force, offering increased flexibility and control, making them a popular choice for medium to heavy-duty applications. Servo-electric press brakes, on the other hand, are known for their energy efficiency and precision, suitable for high-accuracy tasks.

Mechanical press brakes use a flywheel and crank system, ideal for high-speed operations but limited in flexibility. Hydraulic press brakes utilize hydraulic fluid to generate force, offering increased flexibility and control, making them a popular choice for medium to heavy-duty applications. Servo-electric press brakes, on the other hand, are known for their energy efficiency and precision, suitable for high-accuracy tasks.

The metal fabrication equipment market continues to grow, with a reported increase in demand for precision machinery. According to industry reports, the press brake segment specifically is projected to expand significantly, driven by advancements in automation and technology. Recent investments in high-capacity and technologically advanced press brakes reflect this trend, as businesses strive to enhance productivity and fabricating capabilities. Facilities adopting modern equipment like 14-axis press brakes not only improve efficiency but also expand their capacity to handle more complex projects, responding to the increasing demands of the fabrication sector.

Key Factors to Consider When Selecting a Press Brake for Your Business Operations

When selecting a press brake machine for your business operations, it’s essential to prioritize factors that align with your specific needs. The first key consideration is the type of material you will be processing. Different materials, such as aluminum, steel, or stainless steel, require varying tonnages and bending capabilities. This affects the machine's size and power, making it critical to choose a press brake capable of handling your most common materials efficiently.

Another vital factor is the machine's control system. A more advanced control system can significantly improve precision and ease of use, especially for complex shapes and multiple bends. Investing in a machine with a user-friendly digital control interface may reduce operator error and enhance overall productivity.

**Tips:** Always assess your current and future production requirements to select a press brake with adequate capacity and adjustability. Additionally, consider looking for technology upgrades and features that promote automation, as this will support greater efficiency and cost-effectiveness in the long run. Investing in training for your operators can also maximize the machine's potential, ensuring you make the most out of your acquisition.

The Ultimate Guide to Choosing the Right Press Brake Machine for Your Business Needs

This chart represents key factors influencing the choice of press brake machines based on a survey of manufacturing experts. The data illustrates the importance of factors like price, capabilities, brand reputation, and after-sales support.

Evaluating the Technical Specifications that Matter Most in Press Brake Machines

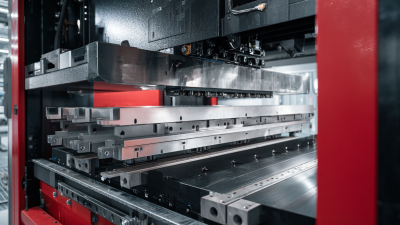

When selecting the right press brake machine for your business, evaluating technical specifications is crucial. One of the primary considerations is the machine's safety features, particularly in light of the recently revised ANSI B11.3-2012 standard, which outlines essential safety requirements for power press brakes. Understanding the available safeguarding options is vital for operators to ensure safety while maintaining productivity. This includes familiarizing oneself with various protective mechanisms that prevent accidents during operation without compromising the machine's efficiency.

Additionally, businesses must pay attention to the material type and thickness they plan to work with, as this directly impacts bending and folding applications. The right press brake should accommodate a range of materials and thicknesses, thus providing versatility in manufacturing processes. These specifications not only dictate the quality of the finished products but also influence operational safety, as improper handling of materials can lead to increased risk for the operator.

Therefore, a thorough evaluation of these technical aspects will guide businesses in selecting the right press brake machine that aligns with their specific operational needs.

Analyzing Cost vs. Value: How to Budget for Your Press Brake Acquisition

When considering the acquisition of a press brake machine, a critical factor is the balance between cost and value. Recent industry reports indicate that the initial investment in a press brake can vary significantly, ranging from $5,000 for entry-level models to over $250,000 for high-end, automated systems. However, it’s essential to analyze the long-term value these machines provide. A study by the Fabricators & Manufacturers Association (FMA) found that businesses often recover their initial investment within three years by evaluating increased production efficiency and reduced labor costs.

Additionally, evaluating the operational costs is vital when budgeting for a press brake. According to the Association of Manufacturing Technology (AMT), machines with higher upfront costs often deliver lower energy consumption and maintenance expenses, leading to overall savings that enhance their value proposition. Investing in technology with advanced features can mean better precision and less material waste, which directly impacts profitability. Therefore, while sticker price is a significant factor, considering the total cost of ownership and the potential return on investment will lead to a more informed decision for your business needs.

Future-Proofing Your Investment: Ensuring Longevity and Versatility in Press Brake Machines

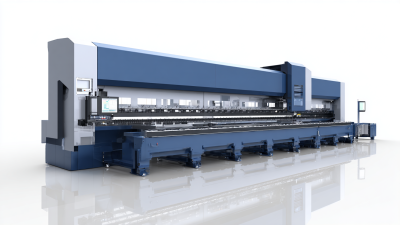

When selecting a press brake machine for your business, future-proofing your investment is essential to ensure longevity and versatility. The rapid advancements in manufacturing technologies mean that machines must adapt to changing production needs and material types. By investing in a press brake that offers flexibility in programming and tooling options, businesses can remain competitive in a fast-evolving market. Features such as CNC controls and the ability to accommodate various bending angles and thicknesses can significantly enhance a machine's lifespan and usability.

Moreover, consider the machine's construction quality and after-sales support. A robust build using high-grade materials can withstand the rigors of heavy use, ensuring that your equipment remains operational for years. Additionally, choosing a supplier that provides comprehensive training, maintenance services, and a readily available parts inventory can further safeguard your investment. By prioritizing these aspects, businesses can ensure that their press brake machines not only meet current demands but are also well-equipped to handle future challenges in manufacturing.

The Ultimate Guide to Choosing the Right Press Brake Machine for Your Business Needs

| Feature | Importance | Example Specifications | Longevity Aspect |

|---|---|---|---|

| Bending Capacity | Critical for production needs | 40 tons up to 200 tons | Choose a model that exceeds current requirements |

| CNC Control System | Enhances precision and repeatability | Hydraulic or Electric CNC options | Upgradable software and intuitive interfaces |

| Back Gauge System | Essential for accurate cuts | Mechanical or servo-driven systems | Precision and adjustments for various materials |

| Tonage Adjustability | Flexible operation for different tasks | Variable tonnage configurations | Allows use for multiple projects over time |

| Frame Construction | Affects stability and quality | Heavy-duty steel vs. cast iron | More durable and less prone to wear |

Related Posts

-

Maximize Your Metalworking Efficiency with the Latest Press Brake Innovations

-

The Future of Precision Engineering with Best Press Brake Technology

-

Maximizing Precision and Efficiency in Fabrication with Advanced Sheet Metal Press Brake Technology

-

Why Small Press Brakes Are Essential for Precision Metal Bending in Modern Manufacturing

-

Exploring the Future of Press Brake Machines at the 138th Canton Fair 2025: Industry Insights and Trends

-

Why Understanding Hydraulic Press Brakes is Essential for Modern Manufacturing